High-power Fiber Lasers and Amplifiers

Definition: fiber lasers and fiber amplifiers with high output powers of e.g. > 10 W

More general terms: fiber lasers and fiber amplifiers

German: Hochleistungs-Faserlaser und -Verstärker

Categories: fiber optics and waveguides, lasers, optical amplifiers

How to cite the article; suggest additional literature

Author: Dr. Rüdiger Paschotta

Whereas the first fiber lasers could deliver only a few milliwatts of output power, there have subsequently been rapid developments which have lead to high-power fiber lasers and particularly amplifiers with output powers of tens or hundreds of watts, sometimes even several kilowatts from a single fiber. This potential arises from a very high surface-to-volume ratio (avoiding excessive heating) and the guiding (waveguide) effect, which avoids thermo-optical problems even under conditions of significant heating.

Fiber laser technology now competes strongly with other high-power laser technologies based on solid-state bulk lasers, such as thin-disk lasers.

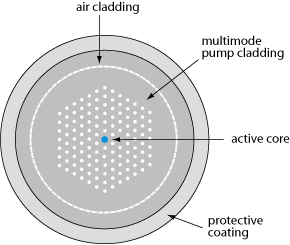

Double-clad Fibers and Beam Quality

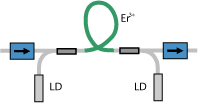

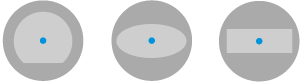

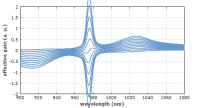

High-power fiber lasers and fiber amplifiers are nearly always realized with rare-earth-doped double-clad fibers, which are pumped with fiber-coupled high-power diode bars or other kinds of laser diodes. The pump light is launched into an inner cladding rather than into the (much smaller) fiber core, in which the laser light is generated. The laser light can have very good beam quality – even diffraction-limited beam quality if the fiber has a single-mode core. Therefore, the brightness of the fiber laser output can be orders of magnitude higher than that of the pump light, even though the output power is of course somewhat smaller. Double-clad fiber lasers can thus effectively be used as brightness converters. Typical optical-to-optical power efficiencies are above 50%, sometimes even above 80%; the overall electrical-to-optical power conversion efficiency of a diode-pumped fiber laser can be of the order of 50% for an Yb-based fiber laser pumped with efficient high-power diode lasers.

For the highest powers, the core area needs to be fairly large (→ large mode area fibers), because the optical intensities would otherwise become too high, and often also because a double-clad fiber with a large ratio of cladding to core area has a weak pump absorption. For core areas up to the order of a few thousand μm2, it is feasible to have a single-mode core. Larger mode areas with still fairly good output beam quality are possible with a slightly multimode core, where most of the light propagates in the fundamental mode. (The excitation of higher-order fiber modes can be suppressed to some extent e.g. by coiling the fiber, except if one obtains strong mode coupling at high power levels [14].) For even larger mode areas, the beam quality can no longer be nearly diffraction-limited, but it can still be fairly good compared with, e.g., rod lasers operating at similar power levels.

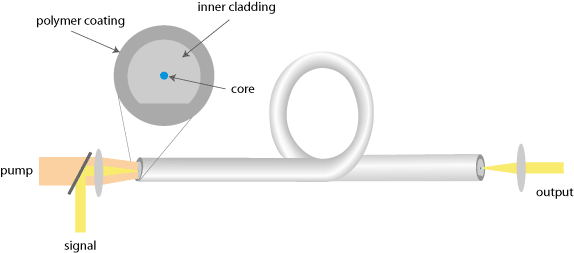

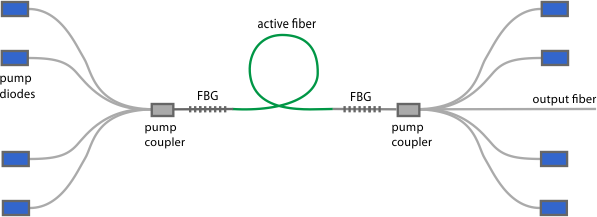

Launching the Pump Light

There are several options for launching pump light at very high power levels. The simplest is to launch directly into the pump cladding at one or both fiber ends (see Figure 2). This technique does not require special fiber components; however, it needs the propagation of the high-power pump radiation through air (with free-space optics) and particularly through an air–glass interface, which is then very sensitive to dust and misalignment. In many cases, it is therefore preferable to use one of several techniques where one employs fiber-coupled pump diodes and keeps the pump light in fibers from there on (see Figure 3). One option is to launch the pump light into passive (undoped) fibers which are wound around the active fiber so that the light is gradually transferred into the active fiber (GTWave fiber). Other techniques are based on special pump combiner devices (fiber-optic pump combiners), where several pump fibers and a single active signal fiber are fused together. Yet other approaches are based on side-pumped fiber coils (fiber disk lasers) [3], or on grooves in the pump cladding through which pump light can be injected. The latter technique allows for multi-point pump injection and thus for a better distribution of the heat load.

A comparison of all the different pump launching techniques is complex, since it involves many aspects: not only the transfer efficiency, but also the loss of brightness, the ease of manufacturing, the flexibility of handling, possible back-reflections, leakage of light from the fiber core back to the pump source, the option to maintain the polarization, etc.

Lasers and Amplifiers

The conceptually simplest option for generating high-power laser light is to build a fiber laser directly with some kind of mirrors on both ends. However, high-power fiber devices are very often built as laser-amplifier combinations, i.e., with a MOFA (master oscillator fiber amplifier) architecture. This concept has several advantages. It is easier to control the emission properties of a lower-power seed laser in terms of linewidth, laser noise, wavelength tunability, pulse generation, etc. Also, the fiber of an amplifier has to stand only a power about equal to the output power, whereas in a laser the intracavity power is higher (even though fiber lasers as high-gain devices allow for strong output coupling). Furthermore, it can be advantageous to use a modular design approach, where amplifier stages can be combined as required. In many cases, particularly when a low-power seed laser is used, one even uses several amplifier stages, typically with increasing mode areas and pump powers along the chain.

Nanosecond Pulses

Many high-power lasers for material processing are Q-switched lasers, generating intense nanosecond pulses. In this regime, fiber devices are limited mainly in terms of peak power: apart from various nonlinearities, self-focusing introduces a hard limit at a few megawatts of peak power, which notably cannot be increased by using larger mode areas. Actually achieved peak powers are usually below 1 MW, even for large mode area fibers. This means that, e.g., pulse energies are limited to a few millijoules if the pulse duration is one nanosecond.

On the other hand, the high gain of fiber devices allows the realization of very flexible MOPA devices with a gain-switched laser diode as seed laser. This approach, unlike Q switching of a laser, allows one, e.g., to modify the pulse duration independently of the pulse repetition rate.

Ultrashort Pulses

The large gain bandwidth of fiber amplifiers allows for the amplification of ultrashort pulses. However, particularly in this regime significant challenges arise from the strong fiber nonlinearity, because high-energy femtosecond pulses have huge peak powers. In addition to the risk of fiber damage, strong nonlinear distortions can result from the fiber nonlinearity, and the high level of chromatic dispersion (including higher-order dispersion) can also be problematic. Particularly if pulse quality matters, these matters need to be carefully considered.

One possible approach is to make fiber-based chirped-pulse amplification systems, where the pulse duration within the amplifier is strongly increased, so that the effect of nonlinearities is accordingly decreased. An alternative to this approach is the amplification of parabolic pulses, where up-chirped pulses experiencing the gain and nonlinearity of the amplifier fiber evolve in a self-similar fashion, and their close to linear chirp makes it possible to obtain a high pulse quality with dispersive compression.

Although the mentioned techniques have allowed for extraordinary performance of fiber-based high-power ultrashort pulse sources (at least for multi-megahertz pulse repetition rates and correspondingly moderate pulse energies), these achievements are usually based on setups which involve a lot of free-space optics and hence lose many of the advantages of fiber systems. An interesting direction is the development of all-fiber ultrashort pulse sources, possibly allowing for a final free-space pulse compressor (e.g. a transmission grating), but eliminating the need to launch pulses from free space into a fiber.

Prospects for Further Improvements

Even though the progress in the development of high-power fiber devices has been tremendous in recent years, various kinds of more or less severe limitations are now encountered, which are expected to slow this progress:

- The optical intensities in high-power fiber devices have been enormously increased. Now they are often close to the damage threshold of the material. Therefore, increased mode areas (→ large mode area fibers) are used, but the limits of this approach have also been more or less reached, at least if very high beam quality is required.

- The power dissipation per unit length has reached values of the order of 100 W/m, which causes significant heating for air-cooled fibers. However, water cooling will allow for significant further increases in power. A longer fiber with lower doping concentration makes the cooling easier, but increases the effect of nonlinearities.

- For fibers which are not strictly single-mode, certain mode instabilities occur at output power levels above some threshold, which is typically a few hundred watts. Such mode instabilities lead to a sudden loss of beam quality and are based on thermal gratings (rapid spatial temperature oscillations) in the fiber.

- Fiber nonlinearities can be disturbing in various ways. Even in continuous-wave devices, the Raman gain can become so high (tens of decibels) that a significant part of the power is transferred to a longer-wavelength Stokes wave, which does not experience laser gain. Single-frequency operation is even much more limited due to stimulated Brillouin scattering, although a number of measures are known to mitigate this effect to some extent. In devices for ultrashort pulses from mode-locked lasers, self-phase modulation can cause strong spectral broadening. In addition, there can be other problems such as nonlinear polarization rotation.

Due to such limitations, high-power fiber devices can – contrary to common opinions – usually not be considered as power-scalable in a strict sense, at least not well beyond the already achieved performance level. (Previous advances have also largely not been achieved with simple power scaling, but with improved fiber designs and pump diodes.) This has important consequences e.g. when fiber laser technology is compared with that of thin-disk lasers. The article on power scaling of lasers discusses this in more detail.

Of course, even without true power scalability, a lot can be done to improve various kinds of high-power fiber devices. An important issue is the further development of advanced fiber designs, e.g. with very large mode areas and single-mode guidance, as often realized with photonic crystal fibers. Various kinds of fiber devices are also important, e.g. special pump couplers, tapers for connecting fibers with different mode sizes and special cooling arrangements. Once the limit of the power per fiber has been reached, beam combining will be a further option – fiber devices appear suitable for this technique. Also for ultrashort pulse amplifier systems there are various interesting options to mitigate and partially even to exploit the fiber nonlinearity, e.g. for further spectral broadening and subsequent pulse compression.

Suppliers

The RP Photonics Buyer's Guide contains 28 suppliers for high-power fiber lasers and amplifiers. Among them:

IPG Photonics

High power kilowatt-class fiber laser sources are available from one to hundreds of kilowatts average power. Housed in rugged cabinets, these systems are designed to operate in industrial manufacturing environments. A variety of beam delivery and process head options provide the ultimate flexibility in optimizing one laser for many different applications. IPG high power industrial fiber lasers are recognized as reliable and productive tools in demanding industries such as automotive, aerospace and oil & gas.

Lumibird

Lumibird manufactures an extensive range of mature and custom-designed optical fiber amplifiers and fiber lasers. High output powers are achieved through the use of double cladding fibers pumped by broad stripe diodes. Several varieties of pumping techniques are used each optimized for specific applications. Lumibird also develops key components for producing unique and innovative light sources.

NKT Photonics

The Koheras BoostiK high power single frequency fiber lasers is an ultra-low noise and narrow linewidth laser. An output power of up to 15 W makes it ideal for laboratory work and experimental research. Choose the operating wavelength freely in the 1 or 1.5-μm range. The excellent beam quality enables efficient frequency conversion. The combination of ultra-low noise, narrow line width and high power output makes the Koheras BOOSTIK laser a highly versatile system for a long range of applications such as optical length and frequency standards, quantum optics/computing & phenomena (optical trapping, Bose–Einstein condensate, atom interferometer, squeezing), nonlinear optics pump source, laser-based metrology (precision laser interferometry, spectroscopy), optical heterodyning and coherent communication and coherent beam combining.

RPMC Lasers

RPMC Lasers offers a variety pulsed and CW fiber lasers and fiber amplifiers with wavelengths between 1.0 and 1.5 microns. These fiber lasers can be configured in an OEM or turnkey system, with pulsed versions available from 500 ps up to 30 ns with rep rates from 10 kHz up to MHz.

Applications include material processing, LIDAR, micromachining, and other others.

Menlo Systems

Menlo Systems' high-power fiber lasers based on erbium or ytterbium doped fiber use polarization maintiaining (PM) components only. Our patented figure 9® laser technology ensures excellent stability and low-noise operation. We offer solutions for scientific research as well as laser models engineered for OEM integration.

Questions and Comments from Users

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Please do not enter personal data here; we would otherwise delete it soon. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him e.g. via e-mail.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.

Bibliography

| [1] | A. Galvanauskas, “Mode-scalable fiber-based chirped pulse amplification systems”, J. Sel. Top. Quantum Electron. 7 (4), 504 (2001), doi:10.1109/2944.974221 |

| [2] | J. Limpert et al., “High-power femtosecond Yb-doped fiber amplifier”, Opt. Express 10 (14), 628 (2002), doi:10.1364/OE.10.000628 |

| [3] | K.-I. Ueda, H. Sekiguchi, and H. Kan, “1 kW CW output from fiber-embedded disk lasers”, Proceedings of the Conference on Lasers and Electro-Optics 2002, Long Beach, USA, May 19–24, 2002, post-deadline paper CPDC4, doi:10.1109/CLEO.2002.1034492 |

| [4] | J. Limpert et al., “500 W continuous-wave fibre laser with excellent beam quality”, Electron. Lett. 39, 645 (2003), doi:10.1049/el:20030447 |

| [5] | W. J. Wadsworth et al., “High power air-clad photonic crystal fibre laser”, Opt. Express 11 (1), 48 (2003), doi:10.1364/OE.11.000048 |

| [6] | H. Sekiguchi et al., “1 kW output laser”, Rev. Laser Eng. 31 (8), 525 (2003), doi:10.2184/lsj.31.525 |

| [7] | Y. Jeong et al., “Ytterbium-doped large-core fiber laser with 1.36 kW continuous-wave output power”, Opt. Express 12 (25), 6088 (2004), doi:10.1364/OPEX.12.006088 |

| [8] | F. Röser et al., “131 W 220 fs fiber laser system”, Opt. Lett. 30 (20), 2754 (2005), doi:10.1364/OL.30.002754 |

| [9] | J. Limpert et al., “High-power rod-type photonic crystal fiber laser”, Opt. Express 13 (4), 1055 (2005), doi:10.1364/OPEX.13.001055 |

| [10] | D. Y. Shen et al., “Highly efficient Er,Yb-doped fiber laser with 188 W free-running and > 100 W tunable output”, Opt. Express 13 (13), 4916 (2005), doi:10.1364/OPEX.13.004916 |

| [11] | J. Limpert et al., “High-power ultrafast fiber laser systems”, J. Sel. Top. Quantum Electron. 12 (2), 233 (2006), doi:10.1109/JSTQE.2006.872729 |

| [12] | J. W. Dawson et al., “Analysis of the scalability of diffraction-limited fiber lasers and amplifiers to high average power”, Opt. Express 16 (17), 13240 (2008), doi:10.1364/OE.16.013240 |

| [13] | D. J. Richardson, J. Nilsson, and W. A. Clarkson, “High power fiber lasers: current status and future perspective”, J. Opt. Soc. Am. B 27 (11), B63 (2010), doi:10.1364/JOSAB.27.000B63 |

| [14] | A. V. Smith and J. J. Smith, “Mode instability in high power fiber amplifiers”, Opt. Express 19 (11), 10180 (2011), doi:10.1364/OE.19.010180 |

| [15] | A. V. Smith and J. J. Smith, “Steady-periodic method for modeling mode instability in fiber amplifiers”, Opt. Express 21 (3), 2606 (2013), doi:10.1364/OE.21.002606 |

| [16] | C. Jauregui et al., “High-power fibre lasers” (a review paper), Nature Photon. 7, 861 (2013), doi:10.1038/nphoton.2013.273 |

| [17] | G. Mourou et al., “The future is fibre accelerators”, Nature Photon. 7, 258 (2013), doi:10.1038/nphoton.2013.75 |

| [18] | J. Jauregui et al., “Simplified modelling the mode instability threshold of high power fiber amplifiers in the presence of photodarkening”, Opt. Express 23 (16), 20203 (2015), doi:10.1364/OE.23.020203 |

| [19] | M. Zervas, “Transverse mode instability, thermal lensing and power scaling in Yb3+-doped high-power fiber amplifiers”, Opt. Express 27 (13), 19019 (2019), doi:10.1364/OE.27.019019 |

| [20] | C. Jauregui, C. Stihler and J. Limpert, “Transverse mode instability”, Advances in Optics and Photonics 12 (2), 429 (2020), doi:10.1364/AOP.385184 |

| [21] | R. Paschotta, “Fiber amplifiers – a technology for many applications”. Part 1: introduction, Part 2: various technical issues, Part 3: examples for fiber amplifier designs |

| [22] | R. Paschotta, tutorial on "Fiber Amplifiers", part 6 on double-clad high-power devices |

| [23] | R. Paschotta, tutorial on "Modeling of Fiber Amplifiers and Lasers" |

See also: fiber lasers, fibers, rare-earth-doped fibers, double-clad fibers, fiber-optic pump combiners, high-power lasers, beam quality, master oscillator fiber amplifier, photonic crystal fibers, chirped-pulse amplification, power scaling of lasers, brightness converters, beam combining, The Photonics Spotlight 2010-01-22

and other articles in the categories fiber optics and waveguides, lasers, optical amplifiers

This encyclopedia is authored by Dr. Rüdiger Paschotta, the founder and executive of RP Photonics Consulting GmbH. How about a tailored training course from this distinguished expert at your location? Contact RP Photonics to find out how his technical consulting services (e.g. product designs, problem solving, independent evaluations, training) and software could become very valuable for your business!

|

If you like this page, please share the link with your friends and colleagues, e.g. via social media:

These sharing buttons are implemented in a privacy-friendly way!