Cold Mirrors

Definition: mirrors which can reduce the heat load in an optical system by reflecting only visible radiation

Alternative term: heat control filters

More general term: dielectric mirrors

German: Kaltlichtspiegel

How to cite the article; suggest additional literature

Author: Dr. Rüdiger Paschotta

Particularly for image projectors which contain some kind of incandescent lamp (e.g. a halogen lamp) as light source for the illumination, there can be a substantial heat load on the optical system. This is essentially because not only the desired visible light is generated, but also the more substantial power in the infrared. That infrared light may be absorbed in optical glasses, for example, heat them up, and cause various kinds of detrimental effects, such as mechanical stress and deformations which cause optical aberrations.

In order to eliminate or at least mitigate that problem, special mirrors (heat control filters) have been developed which can work in two different ways as optical filters for removing infrared light:

- Hot mirrors reflect the infrared radiation while transmitting most of the useful visible light. Such a mirror is simply added to the beam path before the optical components which need to be protected.

- Cold mirrors reflect the visible light, while transmitting or absorbing most of the infrared light. (They are sometimes called heat transmitting mirrors, although strictly speaking they transmit or absorb infrared radiation.) Such a mirror is used as a folding mirror in the optical beam path.

Cold mirrors are realized as dielectric mirrors. They should ideally reflect all visible light, but this is challenging for a dielectric mirror. Therefore, there can be a substantial loss for the shortest and longest parts of the visible wavelength region, i.e., for blue and red light. The substrate will usually transmit the shorter wavelength components of the infrared, while absorbing the longer wavelength components.

The infrared absorption in the mirror substrate may lead to some thermal effects in the mirror, which may more or less degrade the system performance. Such effects can be minimized by using a substrate glass with particularly good thermal resistance, including relatively small thermal expansion. For example, borosilicate glasses and fused silica are suitable for that purpose. Soda–lime glasses are sufficient only for lower powers.

As is common for dielectric mirrors, the reflection spectrum is optimized for a certain angle of incidence – for example, for normal incidence or for 45° – and the performance can be substantially worse for other incidence angles.

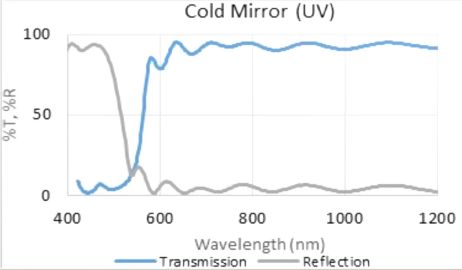

There are also UV cold mirrors, which are reflecting in the ultraviolet region while transmitting visible and infrared light. They are used for processes like semiconductor chip manufacturing and the photopolymerization of inks, dyes or adhesives, where the UV light is needed for the process and other light would be disturbing through thermal or other effects.

Suppliers

The RP Photonics Buyer's Guide contains 21 suppliers for cold mirrors. Among them:

VisiMax Technologies

VisiMax offers various kinds of optical filters, including filters to be used as cold mirrors, which reflect only visible radiation and thus help to reduce the heat low in optical systems.

Edmund Optics

Edmund Optics offers different kinds of cold mirrors, including versions with 0° and 45° angle of incidence and high performance versions with multi-layer dielectric coatings.

Shanghai Optics

Shanghai Optics is a custom optics manufacturer with over 55 years of optics manufacturing experience. Our cold mirrors are perfect for applications that require high reflectance in the visible spectrum and excellent transmission in the infrared. These cold mirrors are manufactured using a special proprietary all dielectric coating technique that yields the most durable commercially available product. Our cold mirrors will pass Mil. C-675, snap tape tests and are capable of operation at temperatures as high as 600°C. They will also operate and survive in extreme humidity environments. Cold mirrors are available from stock in one inch and two inch diameter round or one inch, two inch and four inch square configurations. Larger sheets are also available and may be cut into custom sizes.

Dynasil

EMF, a Dynasil company, offers high transmission cold mirrors that are an excellent choice for preventing undesirable ultraviolet and visible light from damaging or altering the spectral characteristics. It offers two designs for use at either 0° or 45° angle of incidence. These mirrors are typically produced using borosilicate or float glass but are also offered on specialized substrate materials to withstand extremely high-temperature applications.

EMF has supplied 700,000 cold mirrors to a global automotive components manufacturer without a single reported field failure.

Questions and Comments from Users

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Please do not enter personal data here; we would otherwise delete it soon. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him e.g. via e-mail.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.

See also: hot mirrors, dichroic mirrors, optical filters, thermal radiation

and other articles in the category photonic devices

|

If you like this page, please share the link with your friends and colleagues, e.g. via social media:

These sharing buttons are implemented in a privacy-friendly way!