Industrial Lasers

Definition: lasers used for industrial purposes, for example for laser material processing

More general terms: lasers

More specific term: manufacturing lasers

Opposite term: scientific lasers

German: Industrie-Laser

How to cite the article; suggest additional literature

Author: Dr. Rüdiger Paschotta

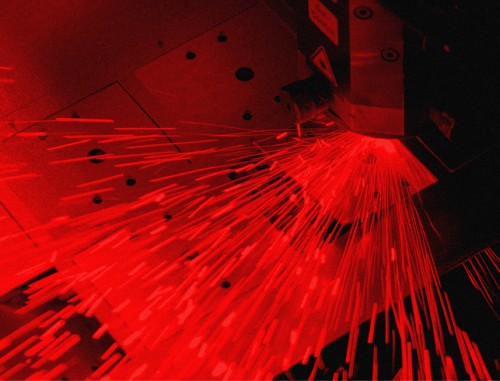

Industrial lasers are lasers for applications in industry. A classical example is a wide range of lasers (or complete laser systems) for use in laser material processing, e.g. for laser cutting, welding and marking. There are various other industrial laser applications such as optical metrology with laser interferometers and laser scanners, optical sampling on semiconductor chips and fiber-optic sensors. Optical fiber communications can in principle also be regarded as an industrial laser application. Most frequently, however, the term industrial lasers is applied in the context of manufacturing.

Special Requirements

The performance specifications for industrial lasers often do not approach the limits of currently available technology. On the other hand, there are often additional requirements which are specific for industrial applications:

Laser Reliability

High reliability over a large number of operation hours is often essential for amortizing the high cost of a laser system. Unexpected interruptions of production processes due to laser failures can be very costly.

Therefore, the laser development needs to pay special attention to reliability issues. For example, one needs to establish a highly reliable supply of optical and other components with well defined quality levels. The laser design must be carefully worked out.

The manufacturing procedures for industrial lasers must be carefully crafted and well defined to be consistently carried out by well trained personnel, and appropriate quality control procedures need to be established. The reliability of the built lasers must often be tested over prolonged times before first devices can be shipped.

In addition, well defined and regularly applied service procedures can be important. For those, typically used spare parts must be kept readily available.

Further, a manufacturer may use special techniques for monitoring lasers during their use. One may use direct data transmission from lasers to the the manufacturer such that the latter can recognize problems early on, for example in order to replace critical parts before they fail, or to initiate cleaning or realignment procedures.

Production Volumes

Industrial lasers are often used in large quantities. That makes it easier for manufacturers to amortize the high cost of laser development. On the other hand, high volume production capabilities need to be built up, because industrial customers may not be willing to accept long waiting times before delivery.

Identifying Laser Applications

It is often essential to recognize laser applications with high economical benefits and to learn about their exact requirements.

It can frequently not be expected that the end user knows the precise conditions under which a certain laser-based manufacturing technique, for example, can be optimally applied. Therefore, it can be highly useful if a laser manufacturer has developed a deep understanding of certain laser-based processes and the optimum laser parameters for those. For the economical success of both parties, that can be more vital than the capability to achieve highest laser performance.

Sales and Marketing, Product Management

Obviously, the sales and marketing marketing as well as the product management of industrial lasers must appropriately address the user group. That allows a supplier to assist the customers in the whole process from the acquisition of suitable lasers to their successful operation. Ideally, a partnership is established where the laser manufacturer can continuously learn more about the price size customer needs and adapt the products and services accordingly.

Industrial Laser Manufacturers

A successful manufacturer of industrial lasers must be able to address the special requirements of this application field as explained above. Some of those requirements are difficult to meet by small laser companies, and particularly by startups. For example, it is difficult to establish the required large volume fabrication capabilities in a company with limited financial resources. Also, the laser development process with various precautions for high laser reliability can be difficult to establish.

For those reasons, industrial lasers are mostly produced by larger manufacturers having different characteristics compared with those for the production of scientific lasers. Such differences concerned not only the technical development and production, but also other aspects such as sales and marketing. If a large laser manufacturer is active in both industrial and scientific lasers, these activities are often pursued in separate branches, which may well cooperate in certain technical areas while having separate management and product development.

OEM Lasers

Industrial lasers are not necessarily sold as complete laser systems, but often in the form of OEM laser modules. That means that a manufacturer supplies lasers to one or more other manufacturers who integrate them into larger machines, for example for laser material processing. Each company can then concentrate on its own areas of responsibility, without a necessity to completely understand the whole system.

See the article on OEM laser modules for more details.

Suppliers

The RP Photonics Buyer's Guide contains 16 suppliers for industrial lasers. Among them:

Light Conversion

The PHAROS is a femtosecond laser system combining millijoule pulse energies and high average powers. PHAROS features a mechanical and optical design optimized for industrial applications such as precise material processing. Compact size, integrated thermal stabilization system and sealed design allow PHAROS integration into machining workstations. The use of solid state laser diodes for pumping of Yb medium significantly reduces maintenance cost and provides long laser lifetime.

Tunable PHAROS parameters include: pulse duration (190 fs – 20 ps), repetition rate (single pulse to 1 MHz), pulse energy (up to 2 mJ) and average power (up to 20 W). Its deliverable power is sufficient for most of material processing applications at high machining speeds. The built-in pulse picker allows convenient control of the laser output in pulse on demand mode. The compact and robust optomechanical design features of PHAROS lead to stable laser operation in varying environments.

PHAROS laser can be equipped with automated harmonics modules. A selection of fundamental (1030 nm), second (515 nm), third (343 nm), fourth (257 nm) or fifth (206 nm) harmonic outputs are available through software control.

Harmonics generators are designed to be used in industrial applications where a single output wavelength is desired. Modules are mounted directly on the output of the laser and integrated into the system.

PHAROS has an option for tunable GHz and MHz burst with burst-in-burst capability – called BiBurst. The distance between burst packet groups is called nanosecond burst, N (MHz-Burst). The distance between sub-pulses in the group is called picosecond burst, P (GHz-Burst). In single pulse mode, one pulse is emitted at a time at some fixed frequency. In burst mode, the output consists of several picosecond burst packets each separated by an equal time period between each packet. Each packet can contain a number of sub-pulses which are also separated by an equal time period between each pulse.

High pulse energy femtosecond laser with flexible BiBurst functionality brings new production capabilities to high-tech manufacturing industries such as consumer electronics, integrated photonic chip manufacturing, stent cutting, surface functionalization, future displays manufacturing and quantum computing.

BiBurst material fabrication areas cover:

- brittle material drilling and cutting

- deep engraving

- selective ablation

- transparent materials volume modification

- hidden marking

- surface functional structuring

IPG Photonics

YLS-AMB Adjustable Mode Beam lasers provide up to 25 kW total output power with independent and dynamic control of the size and intensity of the core and ring beams and automatic tuning of output beam mode parameters. The central core delivers up to 15 kW output power, this flexibility allows processing of a wider range of material thicknesses, improves piercing and cutting speed and quality, as well as optimizing welding performance by virtually eliminating spatter. YLS-AMB provides any combination of a small-spot high intensity bright core to a larger ring-shaped beam allowing processing of a wider range of material thicknesses and as well as optimizing welding performance.

TOPTICA Photonics

TOPTICA's single-frequency diode lasers employ state-of-the-art diode technology to achieve the highest single-frequency output power of any direct diode-based system. For example, the TopMode 405-nm model offers as much as 100 mW – an industry record!

Fluence

JASPER is a 1030-nm high-power femtosecond fiber laser delivering up to 160 µJ and 20 W average power. With truly monolithic all-fiber front-end this laser provides fast warm-up time, unprecedented long-term stability and hands-free operation. Contrary to free space laser amplifiers, fiber amplifiers ensure unbeatable beam pointing stability even in harsh environment.

NKT Photonics

What kind of laser do you need? An ultrafast laser for micromachining? A white light laser for quality control? A low-noise laser for remote sensing? We have a wide range of robust and reliable lasers for industrial applications.

We have lasers for sorting & device characterization, materials & nanostructures, micromachining & display, remote sensing, and atomic, molecular & quantum optics.

Our lasers are robust and reliable, they run for thousands of hours as needed in an industrial environment.

Questions and Comments from Users

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Please do not enter personal data here; we would otherwise delete it soon. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him e.g. via e-mail.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.

See also: lasers, OEM laser modules, laser applications, scientific lasers

and other articles in the category lasers

|

If you like this page, please share the link with your friends and colleagues, e.g. via social media:

These sharing buttons are implemented in a privacy-friendly way!