Arc Lamps

Definition: gas discharge lamps based on an electrical arc, or continuously operating gas discharge lamps

More general term: gas discharge lamps

More specific terms: spectral lamps, krypton lamps, xenon lamps, mercury vapor lamps, metal halide lamps, metal vapor lamps, sodium vapor lamps

German: Lichtbogenlampen, Bogenlampen

Category: non-laser light sources

How to cite the article; suggest additional literature

Author: Dr. Rüdiger Paschotta

Arc lamps have originally been understood as those gas discharge lamps which are based on an electrical arc – not on a glow discharge. That means that the discharge works in a physical regime where the plasma pressure and temperature, the degree of ionization and the power density are relatively high, while the electrical resistance is comparatively small due to the high degree of ionization. The optical spectrum is more or less a continuum, possibly also containing some number of spectral lines. The light-emitting volume is usually quite small. Originally, arc lamps have basically always been carbon arc lamps (see below). Later on, other types of such devices have been developed, for example high pressure xenon lamps.

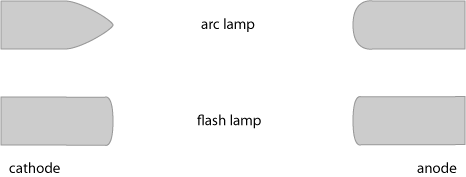

Later on, the meaning of the term has been substantially shifted. One started to use the term arc lamps for any gas discharge lamps which are operated continuously – with a continuous arc rather than a short spark. In that sense, the term arc lamps is just the opposite of a flash lamp, irrespective of what the physical details of the electrical gas discharge are, e.g. concerning gas temperature and pressure. For example, even fluorescent lamps based on a low-pressure mercury vapor discharge may be considered to belong to that category.

One distinguishes short-arc and long-arc lamps. The former have a short distance between anode and cathode, resulting in a relatively small light-emitting volume. That is useful particularly for applications where the generated light needs to be collimated or focused. Higher average powers can be generated with long-arc lamps, where the arc length can be several tens of centimeters.

Arc lamps are usually operated with constant electrical power and light output, but it is also possible to realize modes of quasi-continuous operation, e.g. with a periodically modulated drive current. Note, however, that the resulting thermal cycling can substantially reduce the lamp lifetime. This problem may be mitigated by using specially adapted electrode designs.

In the following sections, a few types of arc lamps in the old sense (with arc discharges) are explained. They all have a small light-emitting volume with high power density and a high plasma temperature. Generally, they cannot be directly operated with line voltage, but need some ballast or more complicated electrical circuit. The lifetime is often relatively limited due to the high stress on the electrodes, but some versions can operate over thousands of hours. Typical applications are those where a relatively high radiance, resulting from a relatively small light-emitting volume, is required – for example, high-power projection displays and directed search lights.

For other types of continuous-wave lamps, and also for additional aspects e.g. of electrodes and lamp envelopes, see the article on gas discharge lamps.

Types of Arc Lamps

Carbon Arc Lamps

The carbon arc lamp is a rather old kind of lamp, which is nowadays nearly obsolete, because it has been largely replaced by other devices such as xenon arc lamps (see below). Its construction is relatively simple. One uses two graphite electrodes with a length of a several centimeters and a diameter of a few millimeters, to which some electric voltage is applied. For starting the arc, the electrodes are brought together with their tips and are surrounded by air. The resulting high current heats up mostly the contact region, and one can soon slowly increase the distance between the electrodes while maintaining an arc between them. The arc develops a rather high temperature (thousands of degrees Celsius) and emits bright white light.

During operation, the graphite electrodes are continuously consumed; the material is oxidized mostly to carbon dioxide gas. Most of the consumed power, however, comes from the electricity source, not from the oxidization of the graphite.

In simple devices, the distance between the electrodes is manually adjusted. That is necessary particularly at an after startup, but also occasionally later on, because the electrodes get shorter. There are also more sophisticated lamp constructions where one electrode (or both) is automatically adjusted e.g. for maintaining a constant electrical current. That can be achieved with a solenoid as electromagnet, which pulls the electrodes apart when the current gets too high.

Carbon lamps have once been common for lighting (illumination) applications, also for bright projection displays. Due to their relatively poor luminous efficacy and short lifetime of the graphite electrodes, and also because of the rapid contamination of nearby optical elements, carbon arc lamps have become largely obsolete. In particular, they have been replaced with xenon and metal halide lamps as described below. For low-power low-brightness applications, incandescent lamps were used, which are themselves more and more replaced with solutions based on light-emitting diodes.

High Pressure Xenon Arc Lamps

Xenon lamps can be made for operation with low or high gas pressure. The high pressure variants, made as high-intensity discharge (HID) lamps, operate in the traditional arc regime with high power density and gas temperature, and emitting bright white light.

The xenon pressure can be several tens of bars. The distance between the tungsten electrodes and the light-emitting volume is rather small – sometimes even with a volume well below 1 mm3. Therefore, the radiance is relatively high. Typically, the cathode has the form of a cone, while the anode has a larger rounded area for improved heat dissipation. High-power versions can have water-cooled electrodes. The lamp envelope is usually made from fused silica (fused quartz), which can become rather hot (hundreds of degrees Celsius) during operation.

Such devices are operated with DC current, allowing the independent optimization of the two electrode shapes and leading to a continuous and stable arc. The required electronics are of course more sophisticated than for simple fluorescent lamps, for example, which can be operated with AC line voltage, using only a simple electrical circuit.

High Pressure Mercury Arc Lamps

There is a wide range of quite different mercury vapor lamps, operating in rather different parameter regions. This includes arc lamps in the original sense, which have various aspects in common with xenon arc lamps: they have similar electrodes and work at similar power levels, e.g. a few hundreds of watts. However, the emission spectrum extends more into the ultraviolet spectral region. They can thus be used for applications like UV lithography and UV curing.

As the mercury pressure depends on temperature, it must build up to the full level during the first few minutes of operation, in which the lamp brightness is substantially lower. In applications where frequent switching is not required (street lighting, for example), they can reach very long lifetimes of over 20,000 hours.

See the article on mercury vapor lamps for more details.

In earlier times, mercury lamps have also been used as a more efficient alternative to incandescent lamps for lighting. However, with their luminous efficacy around 35 to 65 lm/W they can no longer compete with more modern solutions such as metal halide lamps and light-emitting diodes, which can also provide a better white tone than the bluish-white of mercury lamps. In addition, one tries to avoid mercury for environmental reasons.

There are also high-pressure lamps containing both xenon and mercury.

Metal Halide Lamps

Metal halide lamps are also based on an electrical arc, which typically involves argon or xenon, mercury and some metal halides (with bromine or iodine) at a high pressure of the order of 5 to 50 atmospheres. They can produce very bright white light, often with a substantial luminous efficacy, e.g. of the order of 100 lm/W or even more. For visible light generation, this is substantially more efficient than using pure mercury lamps. The color rendering index can be quite high, and modifications of the optical spectrum are possible by adding other metals such as sodium, lithium, potassium and rubidium.

It is sometimes necessary to use an additional optical filter for removing the ultraviolet light, which could be detrimental in various respects, e.g. for the skin and eyes of nearby persons.

Their emission properties and high efficiency make metal halide attractive for high-power lighting (illumination) applications. For example, they are used for lighting in sports arenas, security lighting on parking lots, industrial buildings, theater stages etc., where the efficiency is the main advantage. In other applications, the high radiance is also exploited, and further limits the available alternative solutions; an example are projection displays not only for cinemas, but even as small beamers for home video. Another example are automotive headlamps. Those are often called xenon lamps, although they contain xenon only as a starter gas, which also provides some limited output during the warm-up phase.

For more details, see the article on metal halide lamps.

Arc Lamps for Laser Pumping

Some types of arc lamps are widely used for the pumping of continuous-wave solid-state lasers. They are often based on krypton (which is the dominant solution for YAG lasers), and sometimes or xenon gas or with mercury. These are long-arc high pressure lamps, typically operating at several atmospheres and with substantial current densities. Usually, they have the form of thin cylindrical tubes, which are mounted in parallel to a long laser rod, all within a diffuse reflector in a pump chamber. They look similar to flash lamps for the pumping of pulsed lasers, except that the electrode shapes differ; pointed cathodes are common for arc lamps.

The required power densities are rather high, leading to heat loads of the order of tens of watts per centimeter of arc length (depending on the bore diameter and used gas). Therefore, cooling with deionized water is basically always required.

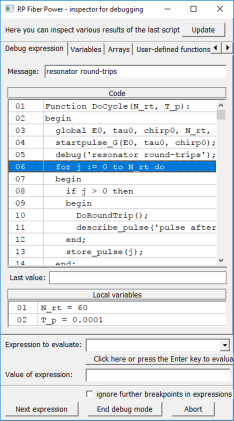

Such arc lamps are often operated with a constant current supply, once they are started. One often applies a startup method where one starts with a relatively low energy high-voltage trigger pulse and then applies a lower-voltage by higher-energy booster pulse before the main power supply for continuous-wave operation can take over. Without the booster, the impedance would not have been sufficiently reduced. See also the article on lamp power supplies.

For efficient laser operation, substantial pump intensities are required. As a typical example, a krypton arc lamp for pumping of a continuous-wave YAG laser may have an arc length of 100 mm, a bore diameter of 5 mm, an operation current of 30 A with a voltage drop of 170 V, and an electric power input of about 5 kW (not including energy losses in the laser power supply). That may be sufficient for a laser output power of the order of 50 W. The wall plug efficiency is then below 1%, depending on the efficiency of the power supply and the power consumption of the cooling system.

Mainly due to the low wall-plug efficiency, the cost for a sophisticated power supply and a powerful cooling system, and also because of the limited lifetime and the low laser beam quality, arc-lamp-pumped solid-state lasers have nowadays largely been replaced with diode-pumped lasers, while pulsed lasers with flash lamps often remain in use.

See the article on lamp-pumped lasers for more details.

Suppliers

The RP Photonics Buyer's Guide contains 16 suppliers for arc lamps.

Questions and Comments from Users

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Please do not enter personal data here; we would otherwise delete it soon. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him e.g. via e-mail.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.

See also: gas discharge lamps, flash lamps, white light sources, lamp-pumped lasers, xenon lamps, high intensity discharge lamps, lamp power supplies

and other articles in the category non-laser light sources

|

If you like this page, please share the link with your friends and colleagues, e.g. via social media:

These sharing buttons are implemented in a privacy-friendly way!